Hydrogen generator DIY takes center stage, inviting you to explore the world of creating your own hydrogen generator. This guide delves into the fundamental principles of hydrogen generation, offering practical insights into various methods, design considerations, and safety protocols. Whether you’re a seasoned tinkerer or a curious beginner, this comprehensive guide will equip you with the knowledge and resources to embark on your own hydrogen generator journey.

Table of Contents

The world of hydrogen generation is captivating, offering a glimpse into the potential of renewable energy. This guide unveils the secrets behind DIY hydrogen generators, allowing you to understand the intricacies of this technology and its applications. From the basic principles of electrolysis to the complexities of design and construction, we explore the multifaceted aspects of building your own hydrogen generator.

Introduction to Hydrogen Generators

Hydrogen generators are devices that produce hydrogen gas, a clean and efficient energy carrier. They are gaining popularity as a potential solution to reduce carbon emissions and transition to a sustainable energy future.

Hydrogen Generation Methods

Hydrogen generation involves extracting hydrogen from its compounds. Several methods are employed for this purpose, each with its own advantages and disadvantages.

- Electrolysis: This method uses electricity to split water molecules (H2O) into hydrogen (H2) and oxygen (O2). Electrolysis is a clean and efficient method, especially when powered by renewable energy sources. However, it can be energy-intensive, and the cost of electricity can impact the overall cost of hydrogen production.

- Steam Reforming: This process involves reacting natural gas (methane) with steam at high temperatures to produce hydrogen and carbon dioxide. Steam reforming is a mature and cost-effective method, but it generates significant carbon dioxide emissions.

- Biological Methods: Some microorganisms can produce hydrogen gas through a process called biohydrogen production. This method is still in its early stages of development but offers potential for sustainable hydrogen production from organic waste materials.

Advantages and Disadvantages of DIY Hydrogen Generators

Building a DIY hydrogen generator can be a rewarding project for enthusiasts, but it’s crucial to understand the risks and limitations.

- Advantages: DIY generators can be cost-effective and offer flexibility in design and customization. They can also provide a hands-on learning experience about hydrogen technology.

- Disadvantages: DIY hydrogen generators often lack safety features and quality control found in commercially available units. They may also be less efficient and have a shorter lifespan. Furthermore, handling hydrogen gas requires specialized knowledge and safety precautions.

DIY Hydrogen Generator Designs

Building a hydrogen generator at home can be a fascinating project, but it’s crucial to understand the inherent risks involved. Hydrogen is highly flammable and explosive, so safety should be your top priority.

This section will delve into common DIY hydrogen generator designs, outlining their components, functionalities, and safety considerations.

Electrolysis-Based Designs

Electrolysis is the most common method for generating hydrogen at home. This process involves splitting water molecules into hydrogen and oxygen using an electric current.

- Simple Electrolysis Cell: This design typically uses two electrodes (often made of stainless steel or graphite) submerged in a solution of water and electrolyte (like baking soda or potassium hydroxide). When an electric current is applied, hydrogen gas is produced at the cathode (negative electrode) and oxygen gas at the anode (positive electrode).

- Membrane Electrolysis Cell: This design employs a semi-permeable membrane to separate the hydrogen and oxygen gases produced during electrolysis. The membrane allows hydrogen ions to pass through but blocks oxygen, resulting in a more concentrated hydrogen stream.

Chemical-Based Designs

These designs utilize chemical reactions to produce hydrogen gas.

- Aluminum-Based Generator: This method involves reacting aluminum with a strong alkali solution (like sodium hydroxide) to produce hydrogen gas. The reaction is highly exothermic and can generate significant heat.

- Sodium Borohydride Generator: This approach involves reacting sodium borohydride with water in the presence of a catalyst (like nickel or cobalt). The reaction releases hydrogen gas and produces sodium borate as a byproduct.

Safety Considerations

DIY hydrogen generators pose significant safety risks due to the flammable nature of hydrogen gas.

- Explosion Hazard: Hydrogen gas is highly flammable and explosive, especially when mixed with air. Proper ventilation and leak detection are essential.

- Electrocution Risk: Electrolysis-based generators involve high voltages, increasing the risk of electric shock. Safety precautions, such as insulated wiring and circuit breakers, are crucial.

- Chemical Hazards: Chemical-based generators often utilize corrosive or toxic chemicals, requiring careful handling and disposal.

Essential Components and Materials

Building a DIY hydrogen generator requires careful selection and assembly of specific components. Understanding the role of each part is crucial for both safety and optimal performance. This section explores the essential components and materials needed for a DIY hydrogen generator, highlighting their importance and providing guidance on choosing high-quality materials.

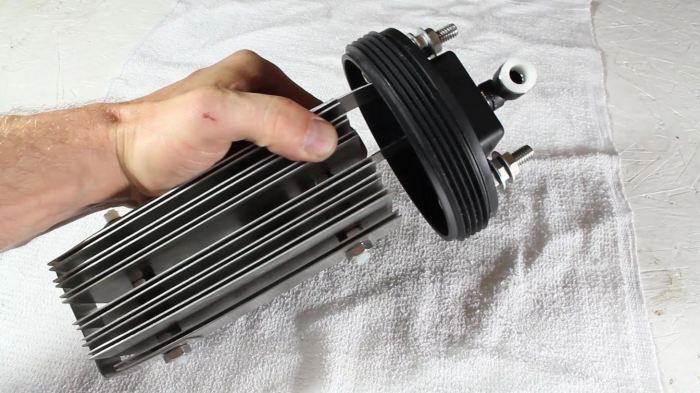

Electrolyzers

The electrolyzer is the heart of a hydrogen generator, responsible for splitting water molecules into hydrogen and oxygen. The efficiency and safety of the generator heavily depend on the electrolyzer’s design and materials. Here are key aspects to consider:

- Type: Two primary types of electrolyzers are commonly used in DIY projects:

- Alkaline Electrolyzers: These are typically less expensive and easier to build, using a potassium hydroxide (KOH) solution as the electrolyte.

- Proton Exchange Membrane (PEM) Electrolyzers: These use a solid polymer membrane as the electrolyte and offer higher efficiency, but they are more complex and expensive.

- Materials: The electrolyzer’s construction materials should be corrosion-resistant and chemically inert to withstand the harsh environment of electrolysis. Common materials include:

- Stainless Steel: A popular choice for its durability and resistance to corrosion.

- Nickel: Often used for electrodes due to its catalytic properties and corrosion resistance.

- Titanium: Highly resistant to corrosion and used for applications requiring high temperatures.

- Efficiency: The electrolyzer’s efficiency is measured by its ability to convert electrical energy into hydrogen. Look for electrolyzers with a high Faradaic efficiency, indicating a minimal loss of energy during the electrolysis process.

Electrodes

Electrodes are crucial components within the electrolyzer, facilitating the chemical reaction of water splitting. They are typically made of conductive materials and play a significant role in the efficiency and longevity of the generator.

- Material: The electrode material is critical for its catalytic properties and resistance to corrosion. Common choices include:

- Nickel: A common choice for its catalytic activity and corrosion resistance.

- Platinum: A highly efficient catalyst but expensive.

- Stainless Steel: Can be used for electrodes but may have lower efficiency compared to nickel or platinum.

- Surface Area: A larger surface area on the electrodes increases the contact area for the reaction, leading to higher efficiency.

- Spacing: The distance between the electrodes affects the current flow and the rate of hydrogen production. Maintaining a proper spacing is crucial for optimal performance.

Storage Tanks

Storing hydrogen safely and efficiently is essential for any hydrogen generator. The storage tank plays a vital role in this process, requiring careful consideration of its material and design.

- Material: The storage tank should be made of a material that is compatible with hydrogen and can withstand the pressure required for safe storage. Common materials include:

- Stainless Steel: A widely used material due to its strength, corrosion resistance, and compatibility with hydrogen.

- Carbon Fiber: Lightweight and strong, offering excellent resistance to hydrogen embrittlement.

- Aluminum: A lightweight option but may require special coatings for hydrogen compatibility.

- Pressure Rating: The storage tank’s pressure rating should be significantly higher than the operating pressure of the generator to ensure safe storage.

- Safety Features: The storage tank should incorporate safety features such as pressure relief valves and burst disks to prevent overpressure and potential explosions.

Other Essential Materials

In addition to the core components, several other materials are needed for constructing a DIY hydrogen generator. These include:

- Electrolyte Solution: For alkaline electrolyzers, a potassium hydroxide (KOH) solution is used as the electrolyte. Ensure the concentration and purity of the KOH solution are appropriate for safe operation.

- Electrical Components: This includes a power supply, wiring, fuses, and connectors. Select components with adequate voltage and current ratings to ensure safe and efficient operation.

- Pressure Gauges: Pressure gauges are essential for monitoring the pressure within the generator and storage tank, ensuring safe operating conditions.

- Safety Equipment: Personal protective equipment (PPE) such as gloves, goggles, and a respirator should always be used when handling hydrogen gas and chemicals.

Importance of High-Quality Materials

Using high-quality materials is paramount for building a safe and efficient DIY hydrogen generator. Substandard materials can lead to:

- Corrosion: This can compromise the structural integrity of the electrolyzer and storage tank, leading to leaks and potential hazards.

- Reduced Efficiency: Poor-quality materials can hinder the electrolysis process, resulting in lower hydrogen production and increased energy consumption.

- Safety Risks: Using unsuitable materials can increase the risk of leaks, explosions, or other accidents.

It is essential to prioritize safety and performance by choosing materials specifically designed for hydrogen applications. Consult with experts or manufacturers for guidance on selecting the appropriate materials for your DIY hydrogen generator project.

Construction and Assembly Process

Constructing a DIY hydrogen generator requires careful planning and adherence to safety protocols. This section Artikels the step-by-step process for building a basic hydrogen generator, highlighting essential safety considerations.

Electrolysis Cell Assembly

The electrolysis cell is the heart of the hydrogen generator, where the water is split into hydrogen and oxygen gases.

- Prepare the Electrodes:

- Use stainless steel plates or rods as electrodes. Ensure they are clean and free from any contaminants.

- The size of the electrodes depends on the desired hydrogen output. Larger electrodes produce more hydrogen.

- Assemble the Electrolysis Cell:

- Use a non-conductive container like a plastic bucket or a glass jar as the electrolysis cell.

- Secure the electrodes in the container, ensuring they are submerged in the electrolyte solution and do not touch each other.

- Maintain a distance of at least 1-2 inches between the electrodes.

- The electrodes should be positioned vertically to maximize surface area contact with the electrolyte.

- Electrolyte Preparation:

- Prepare a solution of potassium hydroxide (KOH) or sodium hydroxide (NaOH) in distilled water.

- The concentration of the electrolyte solution is crucial. A 20-30% solution is typically recommended.

- Use caution when handling these chemicals, as they are corrosive. Wear appropriate protective gear, including gloves, goggles, and a lab coat.

- Connect the Electrodes:

- Connect the positive terminal of a DC power supply to the anode (positive electrode) and the negative terminal to the cathode (negative electrode).

- Ensure the electrical connections are secure and well-insulated to prevent any electrical hazards.

Safety Precautions

Safety should be a top priority when working with hydrogen generators. Here are some essential precautions to take:

- Work in a well-ventilated area: Hydrogen is a highly flammable gas. Ensure adequate ventilation to prevent gas accumulation.

- Avoid open flames and sparks: Keep all sources of ignition away from the generator and the hydrogen gas production area.

- Use appropriate protective gear: Wear gloves, goggles, and a lab coat to protect yourself from the corrosive electrolyte solution.

- Ground the generator: Connect the generator to a ground wire to prevent electrical shock hazards.

- Monitor the generator regularly: Keep a close eye on the generator during operation and stop it immediately if any unusual noises or smells are detected.

Connecting the Components

Once the electrolysis cell is assembled, connect it to the power supply and the hydrogen gas collection system.

- Connect the Power Supply: Use a DC power supply with a voltage output of 12-24 volts. The current output should be sufficient to provide the desired hydrogen production rate.

- Connect the Hydrogen Collection System: Use a suitable container, such as a plastic bottle or a balloon, to collect the hydrogen gas. Ensure the container is leak-proof and has a secure connection to the electrolysis cell.

- Install a Pressure Relief Valve: Incorporate a pressure relief valve to prevent excessive pressure buildup in the hydrogen collection system. This is a critical safety measure to prevent explosions.

Testing and Troubleshooting

Testing a DIY hydrogen generator is crucial to ensure its safe and efficient operation. It’s essential to evaluate the generator’s output, efficiency, and potential issues that may arise during operation.

Testing the Generator’s Output

To determine the hydrogen generator’s output, you need to measure the volume of hydrogen gas produced over a specific time. This can be done using a gas collection method, such as a graduated cylinder or a gas burette.

- Gas Collection Method: A simple method is to use a graduated cylinder filled with water and inverted over a tube connected to the generator’s output. As hydrogen gas is produced, it displaces water in the cylinder, allowing you to measure the volume of gas generated.

- Flow Rate Measurement: Alternatively, you can use a flow meter to measure the rate of hydrogen gas production. Flow meters are available in various types, including bubble meters and electronic flow meters.

Determining Efficiency

The efficiency of a hydrogen generator is determined by the amount of hydrogen produced per unit of energy consumed. It can be calculated by dividing the volume of hydrogen produced by the energy consumed during the generation process.

Efficiency = (Volume of Hydrogen Produced) / (Energy Consumed)

- Energy Consumption: The energy consumed can be measured using a power meter or by calculating the power consumption of the generator’s components.

- Hydrogen Production: The volume of hydrogen produced is measured using the methods described in the previous section.

Potential Issues and Troubleshooting

Several issues may arise during the operation of a DIY hydrogen generator. These can include:

- Low Hydrogen Output: This could be due to a variety of factors, including a weak electrolyte solution, a clogged or blocked electrolyte path, or a malfunctioning electrolysis cell. Check the electrolyte solution’s concentration and ensure the electrodes are clean and properly positioned.

- Leakage: Hydrogen gas is highly flammable, so it’s crucial to identify and address any leaks. Check all connections and seals for any signs of leaks. You can use a soapy water solution to test for leaks; bubbles will appear at the point of leakage.

- Overheating: Electrolysis generates heat, and excessive heat can damage the generator’s components. Ensure adequate cooling and ventilation for the generator.

Monitoring Generator Performance

Regular monitoring of the generator’s performance is essential to ensure its safe and efficient operation.

- Electrolyte Level: Monitor the electrolyte level regularly and replenish it as needed. The electrolyte solution should cover the electrodes completely.

- Electrolyte Concentration: Ensure the electrolyte solution’s concentration remains within the recommended range. A weak solution can reduce the generator’s efficiency, while a strong solution can lead to excessive corrosion.

- Gas Production: Monitor the hydrogen gas production rate to ensure it remains within the expected range.

Applications of DIY Hydrogen Generators

DIY hydrogen generators offer a fascinating avenue for exploring alternative energy sources and experimenting with hydrogen technology. While these generators are primarily for educational and hobbyist purposes, they can be used in various applications, each with its own set of considerations.

Powering Small Devices

DIY hydrogen generators can power small devices like LEDs, small motors, and even simple electronic circuits. This is achieved by using the hydrogen produced to fuel a small fuel cell. The fuel cell converts the chemical energy stored in hydrogen into electrical energy.

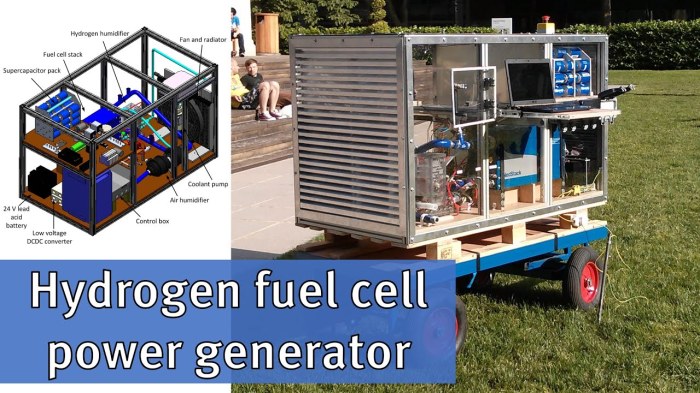

Fuel Cells

DIY hydrogen generators can be used to power fuel cells, which are devices that convert chemical energy into electrical energy. This process involves the reaction of hydrogen with oxygen to produce electricity and water. DIY hydrogen generators can be used to provide the hydrogen fuel for small fuel cells, suitable for powering small appliances, electronics, or even small vehicles.

DIY hydrogen generators are not suitable for powering large-scale fuel cell systems due to their limited output and safety concerns.

Alternative Energy Systems

While DIY hydrogen generators are not a primary source of energy, they can be used in conjunction with other renewable energy sources, such as solar or wind power, to create a more sustainable energy system. For example, a DIY hydrogen generator can be used to store excess energy generated by solar panels, which can then be used to power devices or appliances during periods of low solar irradiance.

DIY hydrogen generators are not a replacement for conventional power sources but can serve as a supplementary source of energy in certain situations.

Safety Precautions and Considerations: Hydrogen Generator Diy

Hydrogen is a highly flammable and explosive gas, making the generation and handling of hydrogen a potentially dangerous process. It is crucial to prioritize safety throughout the entire process, from design and construction to operation and maintenance.

Understanding the Risks

Hydrogen is a colorless, odorless, and tasteless gas that is highly flammable and explosive. It is lighter than air and can quickly disperse, making it difficult to detect leaks. Hydrogen gas can ignite with a spark, flame, or even static electricity. It can also react explosively with oxygen in the air, especially at high concentrations.

Safety Protocols and Protective Equipment

- Always work in a well-ventilated area to prevent the accumulation of hydrogen gas.

- Use appropriate personal protective equipment (PPE), including safety glasses, gloves, and fire-resistant clothing.

- Never smoke or use open flames near a hydrogen generator or storage container.

- Ensure that all electrical connections are properly grounded to prevent static discharges.

- Regularly inspect the generator and its components for leaks and damage.

Preventing Hydrogen Leaks and Explosions

- Use high-quality materials and components for the generator construction.

- Ensure that all connections are tight and leak-free.

- Regularly check for leaks using a soap solution.

- Install pressure relief valves to prevent over-pressurization of the generator.

- Use a hydrogen leak detector to identify leaks in the system.

Hydrogen Leak Detection

Hydrogen leaks can be detected using a variety of methods, including:

- Soap solution: Apply a soap solution to suspected leak points. If bubbles form, it indicates a leak.

- Hydrogen leak detector: These devices are specifically designed to detect hydrogen leaks and are highly sensitive.

- Flame ionization detector (FID): This method is commonly used in industrial settings to detect combustible gases, including hydrogen.

Handling Hydrogen Leaks

In the event of a hydrogen leak:

- Immediately evacuate the area and isolate the leak source.

- Do not attempt to repair the leak yourself.

- Contact a qualified professional to handle the leak.

- Keep the area well-ventilated to prevent the accumulation of hydrogen gas.

Hydrogen Storage

- Hydrogen should be stored in properly designed and certified containers.

- Containers should be stored in a well-ventilated area away from heat and ignition sources.

- Regularly inspect containers for leaks and damage.

Emergency Response

It is essential to have a plan in place for handling emergencies related to hydrogen generation and handling. This plan should include:

- Emergency contact information.

- Procedures for evacuating the area.

- Instructions for using fire extinguishers and other emergency equipment.

Legal and Ethical Considerations

Building and using DIY hydrogen generators comes with legal and ethical implications that must be carefully considered. Understanding the potential environmental impact of hydrogen generation and storage is crucial for responsible development and use of this technology.

Environmental Impact of Hydrogen Generation and Storage

The environmental impact of hydrogen generation depends heavily on the source of energy used to produce it. While hydrogen itself is a clean-burning fuel, its production can release greenhouse gases if fossil fuels are used as the primary energy source.

- Electrolysis: Using renewable energy sources like solar or wind power for electrolysis is the most environmentally friendly method of hydrogen production. However, producing hydrogen through electrolysis requires significant energy input, which needs to be sourced from renewable sources to minimize carbon emissions.

- Steam Methane Reforming (SMR): SMR is a common method of hydrogen production, but it releases significant amounts of carbon dioxide. Carbon capture and storage (CCS) technologies can be employed to mitigate these emissions, but their effectiveness and feasibility remain under debate.

- Hydrogen Storage: Storing hydrogen presents challenges due to its low energy density. Compressed hydrogen storage requires significant energy to compress the gas, while liquid hydrogen storage requires significant energy for liquefaction. Both methods can lead to energy losses and potential environmental impacts.

Responsible Hydrogen Technology Development and Use, Hydrogen generator diy

Promoting responsible hydrogen technology development and use requires addressing the environmental and ethical concerns associated with its production and storage.

- Focus on Renewable Energy Sources: Prioritizing renewable energy sources for hydrogen production is crucial to minimize greenhouse gas emissions. This includes investing in research and development of efficient and cost-effective renewable energy technologies.

- Develop Carbon Capture and Storage Technologies: Investing in research and development of carbon capture and storage technologies is essential to mitigate emissions from hydrogen production using fossil fuels. This can involve developing more efficient and cost-effective CCS technologies and ensuring their safe and long-term storage.

- Promote Hydrogen Safety Standards: Implementing robust safety standards for hydrogen production, storage, and transportation is essential to prevent accidents and ensure the safe use of this technology. This includes developing and enforcing regulations to address potential risks associated with hydrogen handling.

- Ensure Transparency and Public Engagement: Promoting transparency and public engagement in hydrogen technology development and deployment is crucial to build trust and address concerns. This includes providing clear and accurate information about the technology’s potential benefits and risks, and engaging with stakeholders to gather feedback and address their concerns.

Building a DIY hydrogen generator is an exciting endeavor that allows you to harness the power of hydrogen. While this guide provides a comprehensive framework, it’s crucial to approach this project with caution and a strong understanding of safety protocols. With careful planning, meticulous construction, and a commitment to safety, you can unlock the potential of DIY hydrogen generation, contributing to a cleaner and more sustainable energy future.

Building a hydrogen generator at home can be a fun and educational project, but it’s important to prioritize safety. If you’re looking for a more creative DIY endeavor, perhaps consider crafting a jack skellington costume diy for Halloween. While the two projects seem quite different, they both involve understanding the basics of construction and materials. Once you’ve mastered your hydrogen generator, you can move on to more complex projects, or perhaps even a spooky Halloween costume.