DIY thermal camera – the words conjure images of futuristic gadgets and hidden worlds revealed by heat signatures. While the technology behind thermal imaging may seem complex, creating a DIY thermal camera is more accessible than you might think. By understanding the basic principles and utilizing readily available components, you can embark on a journey to build your own infrared vision.

Table of Contents

This guide will walk you through the process, from choosing the right thermal sensor to writing code to process the data. We’ll explore the exciting applications of DIY thermal cameras, from home inspections to wildlife observation, and even delve into the future of this fascinating technology.

Choosing the Right Thermal Sensor

The heart of your DIY thermal camera is the thermal sensor, which detects infrared radiation and converts it into an electrical signal. The sensor you choose will determine the performance and capabilities of your camera.

Types of Thermal Sensors

There are two primary types of thermal sensors commonly used in DIY projects: microbolometer and pyroelectric sensors.

- Microbolometer Sensors: These sensors are the most popular choice for DIY thermal cameras. They consist of tiny, temperature-sensitive resistors that change their resistance based on the amount of infrared radiation they receive. Microbolometers are known for their high sensitivity, good resolution, and relatively low cost.

- Pyroelectric Sensors: These sensors are based on the principle that certain materials generate an electrical charge when their temperature changes. They are often used in simple, low-cost thermal sensors, but they generally have lower sensitivity and resolution compared to microbolometers.

Factors to Consider When Choosing a Sensor, Diy thermal camera

Several factors influence the performance of a thermal sensor and should be considered when making your choice.

- Resolution: The resolution of a thermal sensor refers to the number of pixels it has. Higher resolution sensors provide a more detailed image, allowing you to distinguish smaller temperature differences.

- Sensitivity: Sensitivity, often expressed in millikelvin (mK), measures the smallest temperature difference the sensor can detect. Higher sensitivity allows for more accurate temperature measurements.

- Field of View: The field of view (FOV) refers to the area the sensor can capture. A wider FOV allows you to see a larger area, while a narrower FOV provides a more zoomed-in view.

Popular Thermal Sensors for DIY Projects

Here are a few examples of popular thermal sensors commonly used in DIY projects:

- MLX90614: This microbolometer sensor from Melexis is a popular choice for DIY projects. It offers a resolution of 16×12 pixels, a sensitivity of 0.05°C, and a field of view of 53°x38°.

- AMG8833: This 8×8 microbolometer sensor from Adafruit is another popular option. It has a slightly lower resolution than the MLX90614 but is still suitable for many DIY applications.

- MLX90640: This microbolometer sensor from Melexis is a higher-resolution option, offering a 32×24 pixel resolution. It’s ideal for applications requiring greater detail and accuracy.

Calibration and Accuracy

Calibration is crucial for any thermal camera, DIY or commercially produced, to ensure accurate temperature readings. Without proper calibration, your DIY thermal camera’s measurements will be unreliable, potentially leading to incorrect interpretations and decisions.

Calibration Methods

There are several methods for calibrating a DIY thermal camera, each with its own advantages and disadvantages.

- Blackbody Calibration: A blackbody is a theoretical object that absorbs all radiation that falls on it and emits radiation at a specific temperature. Using a calibrated blackbody source, you can adjust your camera’s settings to match the known temperature of the blackbody. This method provides a high level of accuracy but requires a dedicated blackbody source, which can be expensive.

- Two-Point Calibration: This method involves measuring the temperature of two known objects, such as ice water (0°C) and boiling water (100°C), and adjusting the camera’s settings to match these known temperatures. This method is less accurate than blackbody calibration but is more accessible as it uses readily available materials.

- Software Calibration: Some thermal camera software allows for calibration using a set of reference points. This method is less precise than hardware-based calibration but can be useful for quick adjustments.

Improving Accuracy and Reliability

- Minimize Environmental Factors: External factors like wind, humidity, and sunlight can affect the accuracy of temperature readings. To minimize these effects, shield your camera from these elements during measurement.

- Use Appropriate Materials: The materials used in your DIY thermal camera can influence its accuracy. Choose materials with high thermal conductivity for accurate temperature transfer.

- Regular Calibration: Regularly calibrate your camera to ensure accuracy over time. The frequency of calibration depends on the camera’s usage and the environment it operates in.

DIY Thermal Camera Projects

The world of thermal imaging is no longer limited to expensive professional equipment. With the rise of affordable thermal sensors and open-source hardware, DIY enthusiasts can now build their own thermal cameras for various applications. This section explores some inspiring DIY thermal camera projects, showcasing their diverse applications and design approaches.

Examples of DIY Thermal Camera Projects

These projects demonstrate the potential of DIY thermal cameras in various fields, from home inspection and wildlife observation to security and scientific research.

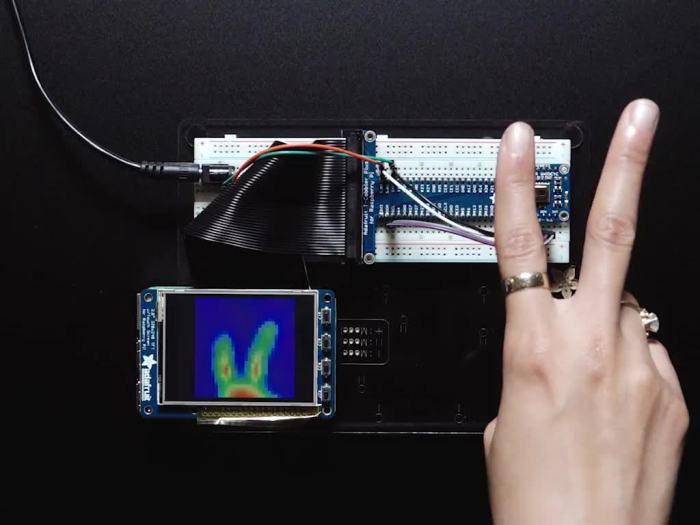

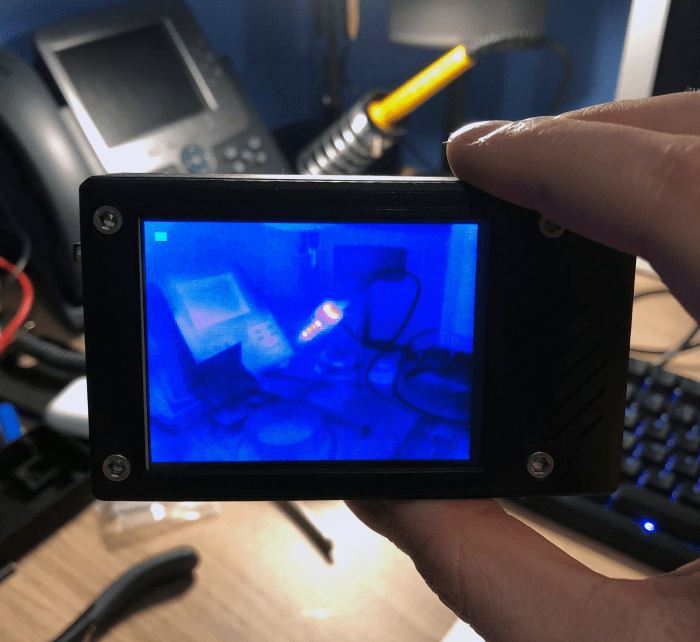

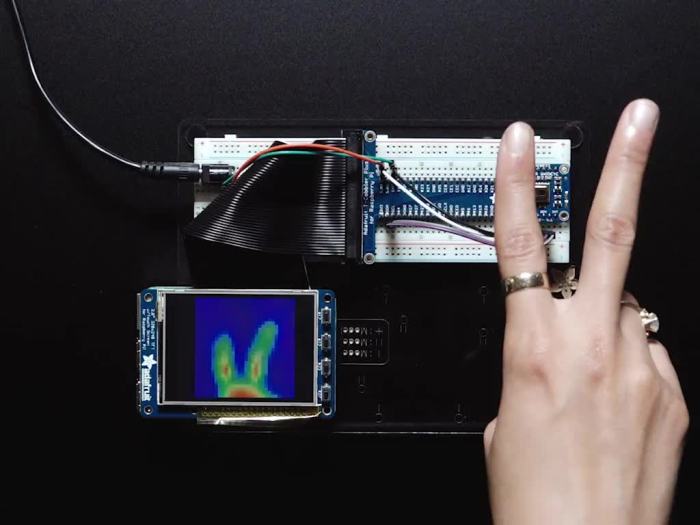

- Raspberry Pi Thermal Camera: This project utilizes a Raspberry Pi, a low-cost single-board computer, and a thermal sensor to create a functional thermal camera. The Raspberry Pi handles image processing and data acquisition, while the thermal sensor captures infrared radiation. This project is popular for its simplicity and affordability, making it an excellent starting point for beginners.

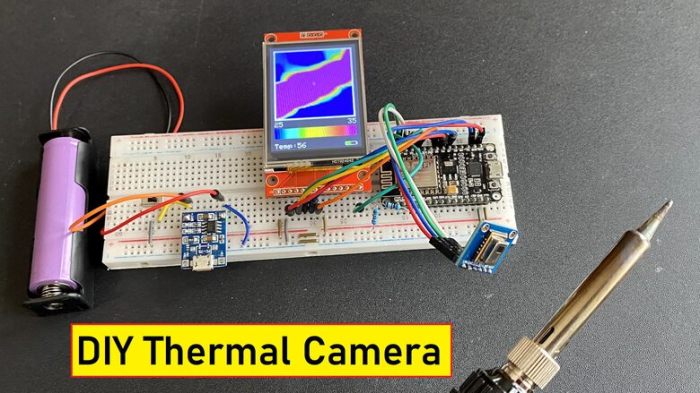

- Arduino Thermal Camera: Similar to the Raspberry Pi project, this project employs an Arduino microcontroller and a thermal sensor to build a basic thermal camera. The Arduino handles the communication with the thermal sensor and displays the thermal image on a connected monitor. This project is suitable for those who are familiar with Arduino programming and electronics.

- Drone-Mounted Thermal Camera: Integrating a DIY thermal camera with a drone opens up exciting possibilities for aerial thermal imaging. This project allows users to capture thermal images from a bird’s-eye view, useful for various applications such as search and rescue, wildlife monitoring, and agricultural inspection.

- 3D-Printed Thermal Camera Housing: A 3D-printed housing can provide a customized and durable enclosure for a DIY thermal camera. This approach allows users to design a housing tailored to their specific needs, ensuring proper protection and functionality.

DIY Thermal Camera Project Table

This table summarizes various DIY thermal camera projects, including their descriptions and links to resources.

| Project Name | Description | Resources |

|---|---|---|

| Raspberry Pi Thermal Camera | A basic thermal camera using a Raspberry Pi and a thermal sensor. | Instructables |

| Arduino Thermal Camera | A simple thermal camera using an Arduino microcontroller and a thermal sensor. | Hackster.io |

| Drone-Mounted Thermal Camera | A thermal camera integrated with a drone for aerial thermal imaging. | YouTube |

| 3D-Printed Thermal Camera Housing | A custom 3D-printed housing for a DIY thermal camera. | Thingiverse |

Future of DIY Thermal Cameras

The DIY thermal camera landscape is constantly evolving, fueled by advancements in technology and a growing community of enthusiasts. The future holds exciting possibilities for DIY thermal cameras, with innovative solutions and applications emerging across various fields.

Emerging Trends and Advancements

The development of thermal imaging technology is rapidly progressing, with several key trends shaping the future of DIY thermal cameras.

- Miniaturization and Cost Reduction: Thermal sensors are becoming smaller and more affordable, making them accessible for DIY projects. This trend is driven by advancements in microelectronics and the increasing demand for thermal imaging in consumer applications. For example, the FLIR Lepton 3.5 thermal sensor is a compact and affordable option for DIY projects, enabling enthusiasts to build their own thermal cameras with ease.

- Improved Image Quality and Resolution: Thermal sensors are achieving higher resolutions and improved image quality, resulting in more detailed and accurate thermal images. This advancement is driven by the development of advanced microbolometer technology, which enables the detection of smaller temperature differences with greater precision. For example, the Optris PI 450 thermal camera boasts a high resolution of 450 x 338 pixels, delivering sharp and detailed thermal images.

- Integration with Other Technologies: Thermal imaging is increasingly being integrated with other technologies, such as artificial intelligence (AI), machine learning (ML), and computer vision. This integration enables the development of sophisticated applications, such as automated object detection, anomaly detection, and predictive maintenance. For instance, researchers are exploring the use of thermal imaging and AI to detect early signs of disease in plants, leading to more efficient and targeted agricultural practices.

Potential for Further Development and Innovation

The DIY thermal camera community is a fertile ground for innovation, with enthusiasts constantly pushing the boundaries of what is possible.

- Open-Source Hardware and Software: The availability of open-source hardware and software platforms allows for greater customization and experimentation with DIY thermal cameras. For example, the Arduino platform provides a flexible and accessible framework for building custom thermal imaging systems.

- 3D Printing and Additive Manufacturing: 3D printing enables the creation of custom enclosures and components for DIY thermal cameras, allowing for greater flexibility in design and functionality. Enthusiasts can design and print custom housings that are tailored to their specific needs, enhancing the portability and usability of their thermal cameras.

- Integration with Drones and Robotics: The integration of thermal imaging with drones and robots opens up new possibilities for applications in various fields, such as search and rescue, environmental monitoring, and infrastructure inspection. For instance, researchers are developing drone-mounted thermal cameras for detecting wildfires and monitoring forest health, providing valuable data for fire prevention and management.

Predictions for the Future

The future of DIY thermal cameras is bright, with several predictions pointing towards a growing role in various fields.

- Increased Accessibility and Adoption: As thermal imaging technology becomes more affordable and accessible, DIY thermal cameras are expected to gain wider adoption in various sectors, from home inspection and security to agriculture and wildlife monitoring.

- Development of New Applications: The integration of thermal imaging with other technologies will lead to the development of innovative applications in fields such as healthcare, manufacturing, and transportation. For example, researchers are exploring the use of thermal imaging for early detection of cancer, enhancing medical diagnostics and treatment outcomes.

- Growing Community and Collaboration: The DIY thermal camera community is expected to continue growing, fostering collaboration and knowledge sharing among enthusiasts. Online platforms and forums will play a crucial role in connecting enthusiasts, sharing resources, and driving innovation in DIY thermal imaging.

Building a DIY thermal camera is a rewarding project that combines electronics, programming, and a touch of ingenuity. It opens up a whole new world of possibilities, allowing you to see the unseen and understand the world around you in a different light. Whether you’re a seasoned electronics enthusiast or a curious beginner, this guide will empower you to embark on your own thermal imaging adventure.

Building a DIY thermal camera can be a fun and rewarding project, but it requires some technical expertise. While you’re working on your electronics project, why not take a break and get creative with some DIY St. Patrick’s Day decorations? You can find inspiration for some amazing decorations here. Once you’re done, you can use your thermal camera to see how well your decorations are holding up against the cold!