Building a deck yourself can be a rewarding project, but it’s essential to understand the costs involved. Cost to build a deck yourself depends on several factors, including the size, complexity, and materials used. This guide will break down the costs associated with materials, labor, permits, and other miscellaneous expenses, helping you make informed decisions throughout the process.

Table of Contents

From planning and design to construction and maintenance, we’ll cover all the essential aspects of building your own deck. We’ll also discuss the pros and cons of DIY versus hiring a contractor, provide cost-saving tips, and address common questions about the project. Whether you’re a seasoned DIYer or a first-timer, this guide will equip you with the knowledge and resources needed to build a beautiful and functional deck that you’ll enjoy for years to come.

Understanding the Cost Factors

Building a deck is a significant investment, and understanding the factors that influence its cost is crucial for budgeting and planning. The cost of building a deck can vary widely depending on several factors, including materials, labor, permits, and miscellaneous expenses.

Deck Size and Complexity

The size and complexity of your deck significantly impact the overall cost. A small, simple deck will naturally cost less than a large, multi-level deck with intricate designs. The amount of materials required, the labor hours needed for construction, and the complexity of the design all contribute to the final price.

For example, a 10×10 foot deck with a simple design will require fewer materials and less labor than a 20×30 foot deck with multiple levels and a built-in seating area.

Materials

The type of materials you choose for your deck will have a substantial impact on the cost. Different materials have varying price points and durability.

- Wood: Traditional wood decking materials like cedar, redwood, and pressure-treated pine offer a classic look and are relatively affordable. However, they require regular maintenance to prevent rot and insect damage.

- Composite: Composite decking materials are a blend of wood fibers and plastic, offering low maintenance and durability. They are generally more expensive than wood but come in a variety of colors and styles.

- PVC: PVC decking is a synthetic material known for its durability, water resistance, and low maintenance requirements. It is often more expensive than composite decking but can last longer.

Labor

Labor costs are a significant portion of the total deck building cost. The amount of labor required will depend on the size, complexity, and location of your deck. Hiring a professional contractor will generally cost more than doing the work yourself.

For example, a contractor may charge $50-$100 per hour, while a DIY project could save you significant labor costs.

Permits

Building permits are often required for deck construction, and the cost can vary depending on your location and the size of your deck. It is essential to check with your local building department for specific requirements and fees.

Permits can range from $100 to $500 or more, depending on the complexity of the project and local regulations.

Miscellaneous Expenses

In addition to the primary costs of materials, labor, and permits, you may also need to budget for miscellaneous expenses such as:

- Foundation: Depending on your deck design, you may need a concrete foundation or other supporting structures.

- Railings: Deck railings are essential for safety and can come in various styles and materials.

- Lighting: Adding lighting to your deck can enhance its ambiance and safety.

- Stairs: If your deck is elevated, you will need stairs to access it.

- Landscaping: Landscaping around your deck can improve its aesthetics and functionality.

Material Costs

The cost of materials is a significant factor in the overall cost of building a deck. Material costs can vary depending on the size and complexity of the deck, the type of wood used, and the location of the project. This section will discuss the various materials needed for deck construction and their associated costs.

Wood Types

The type of wood used for a deck will have a significant impact on the overall cost.

- Pressure-treated lumber: Pressure-treated lumber is a popular choice for decks because it is resistant to rot and decay. It is typically made from pine or spruce and is available in a variety of grades. Pressure-treated lumber is typically more expensive than other types of wood, but its durability makes it a good value in the long run.

- Cedar: Cedar is a naturally rot-resistant wood that is known for its beautiful reddish-brown color. It is more expensive than pressure-treated lumber but is a popular choice for decks that are meant to be visually appealing. Cedar is also a good choice for decks that are located in areas with high humidity.

- Redwood: Redwood is another naturally rot-resistant wood that is known for its beautiful reddish-brown color. It is more expensive than cedar but is a good choice for decks that are meant to be durable and long-lasting. Redwood is also a good choice for decks that are located in areas with high humidity.

- Ipe: Ipe is a tropical hardwood that is extremely durable and resistant to rot, decay, and insects. It is one of the most expensive decking materials available, but its durability makes it a good value in the long run. Ipe is also a good choice for decks that are located in areas with high traffic.

Fasteners

The type of fasteners used for a deck will also affect the overall cost.

- Galvanized nails: Galvanized nails are a common choice for deck construction because they are resistant to rust. They are typically less expensive than other types of fasteners.

- Stainless steel screws: Stainless steel screws are more expensive than galvanized nails but are also more durable. They are a good choice for decks that are located in areas with high humidity.

- Deck screws: Deck screws are specifically designed for use in deck construction. They have a special thread that helps to prevent them from pulling out of the wood. Deck screws are typically more expensive than galvanized nails but are a good choice for decks that are meant to be durable.

Coatings

The type of coating used for a deck will also affect the overall cost.

- Paint: Paint is a common choice for decks because it is relatively inexpensive and easy to apply. However, paint can fade over time and may need to be reapplied every few years.

- Stain: Stain is a good choice for decks because it allows the natural beauty of the wood to show through. Stain is typically more expensive than paint but can last longer. Stain can also help to protect the wood from UV rays and moisture.

- Sealer: Sealer is a good choice for decks because it can help to protect the wood from moisture and UV rays. Sealer is typically more expensive than paint or stain but can last longer.

Material Cost Examples

- Pressure-treated lumber: $4-$6 per square foot

- Cedar: $6-$8 per square foot

- Redwood: $8-$10 per square foot

- Ipe: $15-$20 per square foot

- Galvanized nails: $0.10-$0.20 per pound

- Stainless steel screws: $0.25-$0.50 per screw

- Deck screws: $0.30-$0.60 per screw

- Paint: $20-$40 per gallon

- Stain: $30-$60 per gallon

- Sealer: $40-$80 per gallon

Labor Costs: Cost To Build A Deck Yourself

Labor is a significant part of the overall cost of building a deck. The amount of labor required will depend on the size and complexity of the deck. This section explores the different labor aspects involved in deck construction and compares the cost of hiring a contractor versus doing it yourself.

Labor Involved in Deck Construction

Deck construction involves several stages, each requiring specific skills and expertise. These stages include:

- Site Preparation: This involves clearing the area, grading the ground, and preparing the foundation. It may involve removing existing vegetation, leveling the ground, and installing footings or piers.

- Framing: This involves constructing the deck’s frame, including the joists, beams, and posts. This requires precise measurements and cuts to ensure the deck’s structural integrity.

- Decking: This involves installing the decking boards that form the walking surface of the deck. It requires careful spacing and fastening to create a durable and aesthetically pleasing finish.

- Finishing: This includes adding finishing touches like railings, stairs, and lighting. It may also involve staining or painting the deck.

Cost of Hiring a Contractor vs. DIY

The cost of hiring a contractor versus doing the work yourself is a significant factor to consider.

- Hiring a Contractor: Hiring a contractor offers the benefit of professional expertise and experience. Contractors have the necessary tools, equipment, and knowledge to build a safe and durable deck. However, the cost of hiring a contractor can be substantial, typically ranging from $15 to $45 per square foot.

- DIY: Building a deck yourself can save you money on labor costs. However, it requires significant time, effort, and skills. You will need to purchase the necessary tools and materials and ensure you have the knowledge and experience to complete the project safely and effectively. The cost of materials for a deck can range from $10 to $30 per square foot.

Factors Affecting Labor Costs, Cost to build a deck yourself

Several factors can influence labor costs, including:

- Location: Labor costs can vary significantly depending on the location. For example, labor costs in urban areas tend to be higher than in rural areas.

- Seasonality: Labor costs can fluctuate depending on the season. They tend to be higher during peak construction seasons, such as spring and summer, due to increased demand.

- Project Complexity: The complexity of the deck construction project will also affect labor costs. For example, a complex deck with multiple levels, stairs, and intricate designs will require more labor and therefore cost more.

Permit Costs

Building a deck, especially if it’s attached to your house, usually requires a permit from your local municipality. This is to ensure your deck meets safety standards and local building codes.

Obtaining a Permit

Getting a permit is generally a straightforward process. You’ll typically need to submit a detailed plan of your deck, including its dimensions, materials, and construction details. This may involve working with a professional draftsperson or architect.

Factors Influencing Permit Fees

Several factors influence the cost of a deck permit. These include:

- Deck Size: Larger decks usually incur higher permit fees.

- Location: Permit fees can vary depending on the municipality. Some areas have higher fees than others.

- Local Regulations: Different areas have varying building codes and regulations, which can impact the permit cost. For example, decks in areas with strict seismic requirements might have higher fees.

Typical Permit Costs

Permit costs can range widely, depending on the factors mentioned above. Here are some examples of typical permit costs in different areas:

- Small deck (under 100 square feet): $100 – $300

- Medium deck (100 – 200 square feet): $200 – $500

- Large deck (over 200 square feet): $300 – $1000 or more

DIY vs. Hiring a Contractor

Building a deck can be a rewarding project, but it also requires significant time, effort, and expertise. Before you start, you need to consider the pros and cons of building a deck yourself versus hiring a contractor.

Factors to Consider

Deciding whether to build a deck yourself or hire a contractor depends on various factors, including your skills, available time, budget, and desired outcome.

- Skills and Experience: Building a deck requires a variety of skills, including carpentry, construction, and basic knowledge of building codes. If you lack the necessary skills, hiring a contractor is recommended.

- Time Commitment: A DIY deck project can take weeks or even months to complete, depending on the size and complexity of the deck. Hiring a contractor can significantly reduce the time required.

- Budget: Building a deck yourself can be cheaper than hiring a contractor, but you need to factor in the cost of tools, materials, and potential mistakes. Hiring a contractor may be more expensive but can save you time and ensure a professional outcome.

- Desired Outcome: If you want a high-quality deck that meets specific design requirements, hiring a contractor may be the better option. Contractors have experience, expertise, and access to professional-grade materials.

Advantages of DIY Deck Construction

Building a deck yourself offers several advantages, including:

- Cost Savings: You can save money on labor costs by doing the work yourself. However, remember to factor in the cost of tools, materials, and potential mistakes.

- Sense of Accomplishment: Completing a deck project yourself can provide a strong sense of accomplishment and satisfaction.

- Customization: You have complete control over the design and construction of your deck, allowing you to customize it to your specific needs and preferences.

- Learning Experience: Building a deck is a great way to learn new skills and gain valuable experience in carpentry and construction.

Disadvantages of DIY Deck Construction

While building a deck yourself can be rewarding, it also presents several challenges:

- Time Commitment: DIY deck projects can be time-consuming, requiring significant time and effort. You need to factor in the time needed for planning, purchasing materials, and completing the construction.

- Skill Requirements: Building a deck requires a variety of skills, including carpentry, construction, and basic knowledge of building codes. If you lack these skills, the project can be challenging and potentially unsafe.

- Potential for Mistakes: Mistakes can be costly in terms of time, materials, and safety. If you’re not experienced, you may make mistakes that could compromise the structural integrity of the deck.

- Physical Demands: Building a deck can be physically demanding, requiring lifting, carrying, and working in various positions. If you have physical limitations, this may be a challenging project.

- Safety Concerns: Building a deck involves working with power tools and heavy materials, which can be dangerous if proper safety precautions are not taken.

Advantages of Hiring a Contractor

Hiring a contractor offers several advantages, including:

- Professional Expertise: Contractors have years of experience and expertise in building decks, ensuring a professional and high-quality outcome.

- Time Efficiency: Contractors can complete the project quickly and efficiently, saving you time and effort.

- Quality Materials: Contractors typically have access to high-quality materials and can ensure the deck is built to code and meets safety standards.

- Warranty and Insurance: Contractors usually offer warranties on their work and are insured, providing peace of mind in case of accidents or defects.

Disadvantages of Hiring a Contractor

Hiring a contractor also has some disadvantages, including:

- Higher Cost: Hiring a contractor is generally more expensive than building a deck yourself, as you’re paying for their labor and expertise.

- Limited Customization: You may have less control over the design and construction of the deck when hiring a contractor, as they may have their own preferences and methods.

- Potential for Delays: Delays can occur due to weather, material availability, or other unforeseen circumstances.

Skills and Resources for DIY Deck Construction

If you decide to build a deck yourself, you need to have the following skills and resources:

- Carpentry Skills: You need to be comfortable working with wood, measuring, cutting, and assembling various components.

- Construction Knowledge: You need a basic understanding of building codes, structural requirements, and safety regulations.

- Tools and Equipment: You’ll need a variety of tools, including a saw, drill, hammer, level, and measuring tape. You may also need to rent specialized equipment like a post-hole digger or a concrete mixer.

- Materials: You need to purchase all the necessary materials, including lumber, fasteners, concrete, and paint or stain.

- Time and Patience: Building a deck requires significant time and patience. Be prepared for delays and unexpected challenges.

Risks and Challenges of DIY Deck Construction

Building a deck yourself involves several risks and challenges, including:

- Structural Integrity: Mistakes in construction can compromise the structural integrity of the deck, leading to safety hazards and potential collapse.

- Building Codes: Failing to meet building codes can result in fines or even the need to demolish and rebuild the deck.

- Safety Hazards: Working with power tools and heavy materials can be dangerous if proper safety precautions are not taken.

- Increased Costs: Mistakes can lead to increased costs for materials and labor, especially if you need to hire a contractor to fix errors.

- Time Delays: Delays can occur due to weather, material availability, or your own lack of experience.

Cost-Saving Tips

Building a deck can be a significant investment, but there are several ways to reduce the overall cost without compromising quality. By implementing smart strategies and making informed decisions, you can stretch your budget and create a beautiful and functional outdoor space.

Using Recycled Materials

Using recycled materials can significantly reduce the cost of building a deck. Recycled lumber is often available at a fraction of the cost of new lumber, and it can provide a unique and sustainable look to your deck.

- Recycled plastic lumber is a durable and low-maintenance alternative to traditional wood. It is resistant to rot, insects, and moisture, making it a good choice for decks in areas with high humidity or heavy foot traffic.

- Recycled composite decking is made from a blend of recycled wood fibers and plastic. It is a popular choice for decks because it is durable, low-maintenance, and comes in a variety of colors and styles.

While using recycled materials can be a cost-effective way to build a deck, it’s important to consider the potential trade-offs. Recycled materials may not be as strong or durable as new materials, and they may not be available in all sizes and styles.

Purchasing Materials in Bulk

Buying materials in bulk can offer significant discounts, especially for large projects like building a deck. This is a simple and effective way to save money, but it’s essential to have a plan in place to ensure you’re purchasing the right amount of materials and that you have adequate storage space.

- Check with local lumberyards and home improvement stores to see if they offer discounts for bulk purchases.

- Consider purchasing materials from a supplier that specializes in bulk orders.

- Organize your materials to prevent waste and ensure you have enough for the entire project.

Doing Some of the Work Yourself

Taking on some of the construction tasks yourself can save you money on labor costs. This is a great way to save money, but it’s important to be realistic about your skills and abilities.

- Start with simpler tasks, such as painting, staining, or assembling deck furniture.

- Gradually take on more challenging tasks as you gain experience and confidence.

- Don’t be afraid to ask for help from friends or family members who have construction experience.

If you’re not comfortable doing certain tasks, it’s always best to hire a professional. This will ensure that the job is done correctly and safely.

Planning and Design

Planning and designing your deck is a crucial step in ensuring a successful project. A well-thought-out plan will help you determine the necessary materials, labor, and costs, as well as avoid costly mistakes later on.

Deck Layout Design

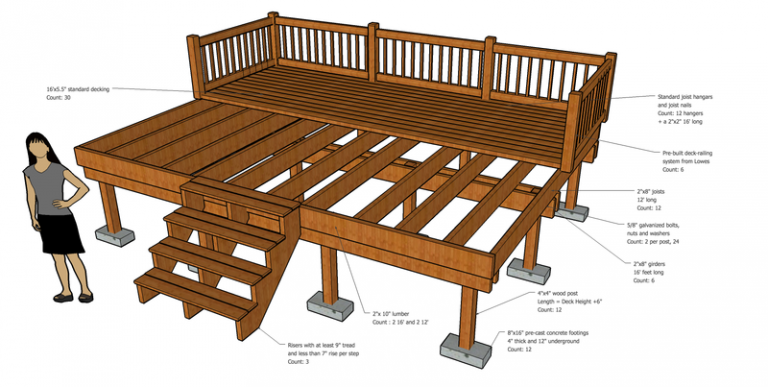

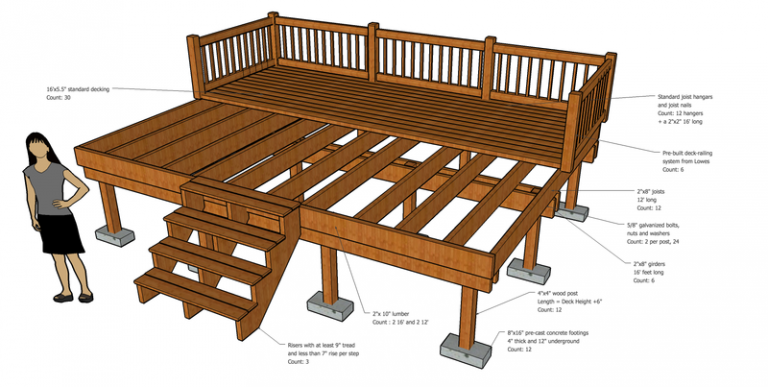

Before you start building, it’s essential to create a detailed deck layout plan. This plan will serve as your blueprint, guiding you throughout the construction process. A well-designed layout should consider your space, desired features, and functionality. Here’s an example of a basic deck layout:

| Component | Dimensions | Materials | Estimated Cost |

|---|---|---|---|

| Deck Platform | 12′ x 16′ | Pressure-treated lumber (2×10 joists, 2×6 decking) | $1,000 – $1,500 |

| Stairs | 3′ wide, 6 steps | Pressure-treated lumber (2×12 stringers, 2×6 treads, 2×4 risers) | $500 – $700 |

| Railings | 36″ high, 2×4 posts, 2×4 rails, 1×4 balusters | Pressure-treated lumber | $400 – $600 |

| Seating Area | 8′ x 10′ | Pressure-treated lumber (2×10 joists, 2×6 decking) | $400 – $600 |

The estimated costs are based on average prices and may vary depending on your location, material choices, and labor costs.

Importance of Proper Planning and Design

A well-planned deck project can save you time, money, and frustration in the long run. Proper planning and design will:

- Ensure a safe and structurally sound deck: A well-designed deck will meet local building codes and regulations, guaranteeing safety and stability.

- Maximize your space: A thoughtful layout can optimize your deck’s functionality, providing ample space for seating, dining, or other activities.

- Minimize waste and costs: Accurate measurements and material calculations will help you purchase the right amount of materials, preventing unnecessary waste and cost overruns.

- Prevent costly mistakes: Planning ahead allows you to identify and address potential issues before construction begins, avoiding costly rework and delays.

- Help you visualize the final product: A detailed plan provides a clear picture of how your deck will look and function, ensuring you’re satisfied with the final result.

Safety Considerations

Building a deck is a rewarding project, but it’s crucial to prioritize safety throughout the process. This section will Artikel essential safety measures to ensure a secure and durable deck for years to come.

Using Proper Tools and Equipment

Using the right tools and equipment is paramount for a safe and efficient deck construction process.

- Power Tools: Always use power tools according to manufacturer instructions. Wear safety glasses, gloves, and hearing protection. Ensure the tools are properly maintained and in good working order.

- Ladders: Inspect ladders before each use, ensuring they are sturdy and free from damage. Always use a ladder on a stable surface and never overextend your reach.

- Hand Tools: Use hand tools with caution, especially when working with sharp objects like saws, knives, or chisels. Always wear gloves to protect your hands.

Following Building Codes

Building codes are designed to ensure the structural integrity and safety of your deck.

- Local Regulations: Consult your local building department to obtain the necessary permits and understand the specific requirements for deck construction in your area.

- Structural Design: Ensure the deck’s design meets local building codes for load-bearing capacity, including snow, wind, and live loads.

- Inspection: Schedule inspections by a qualified building inspector at various stages of construction to verify compliance with building codes.

Working Safely at Heights

Working at heights poses inherent risks, so it’s essential to take precautions.

- Fall Protection: Use safety harnesses, ropes, and fall arrest systems when working at heights. Install guardrails around the deck perimeter.

- Stable Platforms: Ensure all work platforms are stable and secure. Use scaffolding or ladders with proper safety features.

- Weather Conditions: Avoid working at heights during inclement weather, such as strong winds or rain.

Structural Integrity and Load-Bearing Capacity

The structural integrity of a deck is crucial for its safety and longevity.

- Foundation: The foundation should be strong enough to support the weight of the deck and any loads it will bear. Consider soil conditions and consult with a structural engineer if needed.

- Joists and Beams: Use properly sized and spaced joists and beams to ensure adequate load-bearing capacity. Follow building code requirements for joist spacing and beam sizes.

- Fasteners: Use high-quality fasteners, such as structural screws or bolts, to secure the deck components. Avoid using nails, which can pull out over time.

Safety Measures for a Durable Deck

Implementing safety measures during construction helps create a durable deck that can withstand the elements.

- Pressure-Treated Lumber: Use pressure-treated lumber for the foundation, joists, and beams to resist rot and insect damage.

- Waterproofing: Properly waterproof the deck to prevent water damage. Use waterproof membranes or sealants to protect the deck from moisture.

- Regular Maintenance: Regularly inspect and maintain the deck to address any potential issues early on. This includes checking for loose boards, rot, or insect infestation.

Maintenance and Longevity

A deck, like any outdoor structure, requires regular maintenance to ensure its longevity and safety. Neglecting maintenance can lead to premature deterioration, posing safety hazards and requiring costly repairs.

Factors Affecting Deck Longevity

The lifespan of a deck is influenced by a combination of factors, including material choice, construction techniques, and environmental conditions.

- Material Choice: Different materials have varying lifespans. Pressure-treated lumber, while affordable, can be susceptible to rot and insect damage, requiring more frequent maintenance. Composite decking, on the other hand, offers greater resistance to moisture and insects, extending its lifespan.

- Construction Techniques: Proper construction techniques, such as using adequate fasteners, ensuring proper drainage, and adhering to building codes, contribute significantly to a deck’s longevity.

- Environmental Conditions: Exposure to sunlight, rain, snow, and extreme temperatures can accelerate wear and tear on a deck. Decks in humid climates or areas with heavy rainfall require more frequent maintenance to prevent moisture damage.

Cleaning and Sealing

Regular cleaning and sealing are crucial for maintaining a deck’s appearance and extending its life.

- Cleaning: Sweep or brush the deck regularly to remove debris and dirt. Use a mild detergent solution and a soft-bristled brush for deeper cleaning. Avoid harsh chemicals that can damage the wood.

- Sealing: Sealing a deck helps protect it from moisture, UV rays, and stains. Apply a sealant every 1-2 years, depending on the type of wood and climate.

Repairing

Minor repairs, such as replacing loose boards or fixing cracks, should be addressed promptly to prevent further damage.

- Loose Boards: Tighten loose screws or replace them with longer ones.

- Cracks: Fill small cracks with wood filler or epoxy. Larger cracks may require replacing the affected board.

- Rotting Wood: Replace any rotting wood as soon as possible to prevent further damage.

Ending Remarks

Building a deck yourself can be a fulfilling experience, offering a sense of accomplishment and the satisfaction of creating something unique. By understanding the costs, planning carefully, and taking necessary precautions, you can turn your DIY deck project into a successful and enjoyable endeavor. Remember to prioritize safety, use high-quality materials, and seek professional guidance when needed. With careful planning and execution, you can create a deck that enhances your home and provides a welcoming space for relaxation and entertainment.

Building a deck yourself can be a rewarding project, but it’s important to factor in all the costs. From lumber and hardware to tools and permits, the expenses can quickly add up. However, if you’re comfortable with DIY, you might be able to save some money by taking on the project yourself.

Just remember to check your router’s settings and download the latest realtek wifi driver if you’re working from your laptop or tablet. With a little planning and effort, you can create a beautiful and functional deck that will enhance your outdoor living space.